Clear Lagoons

Pondster™ Advanced Purification Technology

Game Changer

Advanced Technology

The Pondster™ is a compact, advanced wastewater treatment technology system specifically designed to treat wastewater in outdoor ponds and lagoons used by commercial and industrial operations. Our “Pond Monster” (Pondster™) eats pond effluent all day long!

- The new Pondster is a game changer for commercial and residential businesses that employ waste ponds.

- It’s an affordable, containerized, “Pond Water Machine in a Box™”.

- It’s designed and built for roll-in and roll-out deployment.

- Pondster has easy to use plug-n-play connections on the outside of the box.

- It offers operator friendly add-ons with existing connection ports.

- Requires low maintenance.

- Delivers quick results.

Waste Ponds

The Problem

Most Mobile Home Parks (MHPs) and many low-population rural residential developments and commercial sites in the Southern and Midwestern States use open air waste ponds or waste stabilization lagoons. 70% of the wastewater in MHPs is not treated and poured into these open air ponds in concentrations too heavy for fresh air and sunlight to manage naturally.

Other residential and business establishments operate similarly where there is no public sewer access. Some employ a combination septic tank/waste stabilization lagoon. Either require proper waste treatment or water quality, health problems and nuisance conditions will result.

* Local and state governments are cracking down with big fines.

The Solution

A Pondster on the Shoreline

- Small containerized “Water Treatment in a Box™”

- Drive in. Plug in.

- Drop a hose in the water.

- Optional upgrade with floating aeration device.

- Increased oxygenation organically accelerates the system’s essential micro-biotic, bacterial effluent conversions.

The Machine

Uses the Latest Tech

Pondster is a modular mobile packaged wastewater treatment system designed to treat pond and lagoon wastewater. It is a perfect application for temporary or permanent installations in need of a fast and easy delivery solution that is incredibly rugged and designed to last for decades while operating under the harshest of conditions.

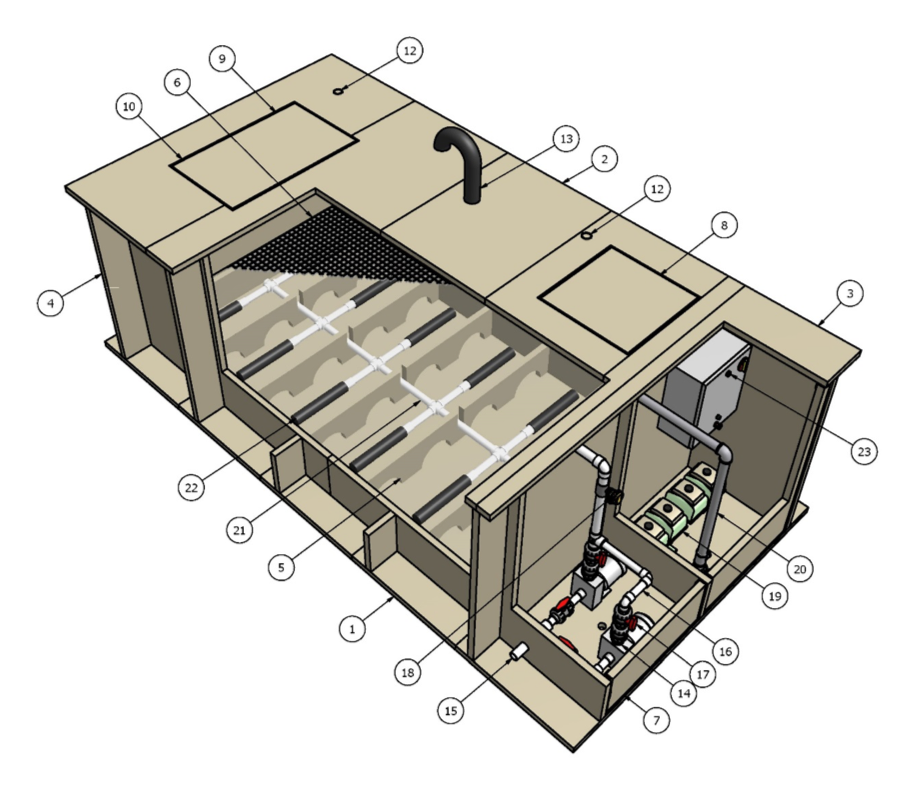

Pondster utilizes the latest advancements in wastewater technology including stationary fixed film bioreactors complemented by IoT operated sensors and other function controllers that are integrated with easy to use computer touchscreens.

These features and PLCs (programable logic controllers) ensure maximum and efficient operation and wastewater treatment. Wastewater treated using Pondster biofilm processes may be suitable for reuse and reclamation purposes such as irrigation, dust control, or simply to meet expel treatment regulations.

Equipment Specifications

- 8’ w x 9.5’ H x 20’ L external dimensions.

Integral equipment includes: - Aeration blowers and piping systems.

- Water pumping and piping systems.

- Porous ceramic media system.

- Telemetry sensors and meters.

- Flex hose systems (inlet & outlet).

- Electrical systems (master control panel).

- Multi-compartment polypropylene tankage system (reinforced, covered and vented).

- Maximum power demand: 10 Kilowatts.

- Approximate shipping weight: 5,000 lbs.

Capability and Results

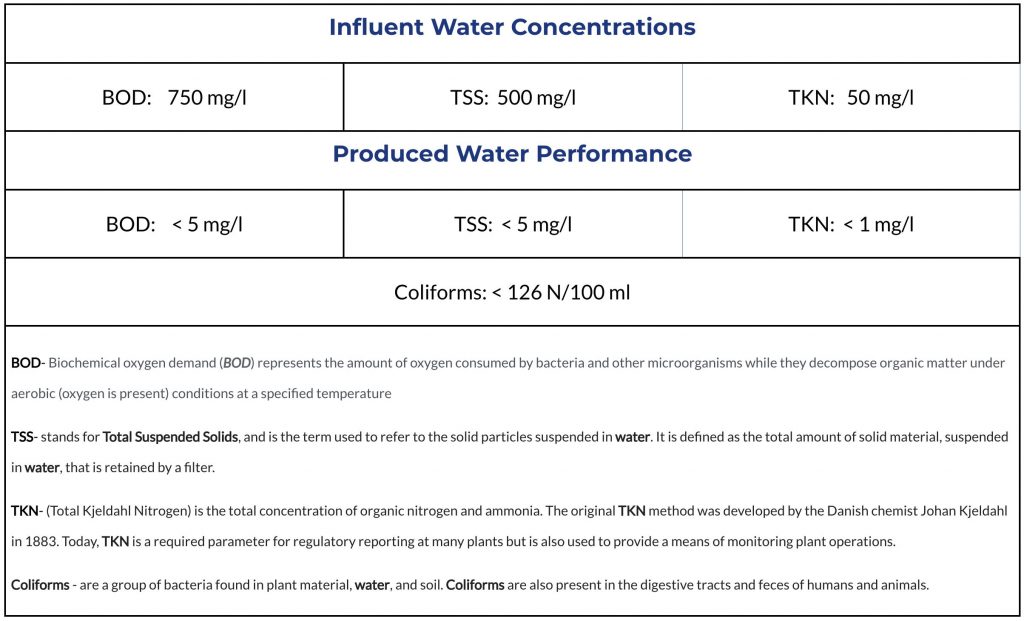

Pondster is designed for high Strength Domestic Wastewater. It handles capacities from 2,500 to 25,000 GPD (gallons per day)* At peak flow the unit can run at 2X the design flow for short periods of time. During low flow operations Pondster will maintain performance compliance at sustained flows less than 10% of the design volume.

Stationary Fixed Film Bioreactors

Fixed Film Bioreactor

The Pondster uses a Stationary Fixed Film BioReactor specifically designed to treat the waste in ponds and lagoons. Our “Pond Monster” (Pondster) eats pond effluent all day long!

A Living Machine

The Sequencing Batch Reactors (SBR) is one of our leading technologies used for wastewater treatment. It accomplishes liquid-solids clarification in a single step process. It is a biological process, a living machine.

The key term is a living machine. A biological treatment is extremely efficient. We’re able to leverage the biological aspects of naturally occurring, bacterial capabilities that exist in the environment which gives us the ability to build machines that can do really phenomenal things.

That allows us to reuse water for a lot of different things. This one is designed for lagoon systems where you want to augment or provide some form of a supplemental treatment process, when you may not be able to achieve all of your treatment with an existing lagoon system.

Variations

We have three different versions of this machine. The unit shown above is rated at 30,000 gallons per day. It’s not a big flow, but with the Modular Water Systems™ product lines were all about decentralization, and in decentralization we typically see smaller treatment systems and smaller applications.

The corrosion resistant, structurally reinforced thermoplastic box is sixteen and a half feet long, five feet tall and eight and a half feet wide. Inside the structure is a compact and sophisticated enclosed equipment room. This machine is truly a plug-and-play technology.

Stationary Fixed Film

This system utilizes a different version of a living machine. We are using what we refer to as a stationary fixed film, an extremely porous ceramic media, which fosters the development of a very robust, highly capable biofilm. Biofilm is a sticky bacteria, natural microorganisms that live within the porous media. We pump our water through this wastewater treatment unit under aeration, so we have diffused aeration systems that are underway providing atmospheric oxygen. We have nutrients in the form of the wastewater pollutants that are in the lagoon. And when we put the biofilm technology in the reactor, we’re just providing a perfect environment for the biology and for the bacteria to provide the wastewater treatment process.

Consumption of Nutrients

The biofilm consumes the carbon by oxidizing it through natural metabolic activity. It will consume and readily address nutrients in the form of nitrogen and phosphorus. This is one of the beautiful things about a very robust, next-order type biofilm process.The system is very energy-efficient for a 30,000 gallon per day process. Our peak instant power demand would be about one kilowatt of total power at any time.

Pondster is the perfect application for temporary or permanent installations. This is your fast and easy delivery solution that both incredibly rugged and designed to last for decades of operating under the harshest of conditions. Pondster utilizes the latest advancements in wastewater technology along with easy to use computer touchscreens that will help to ensure efficient wastewater treatment. Wastewater treated by our Pondster MBR process will also be suitable for reuse and reclamation purposes such as irrigation, dust control, and toilet reflush.

The Pondster is OriginClear’s innovative solution to clean pond effluent all day long. With the Pondster, you will get first-rate custom-built hardware built in Texas.

- Our new Pondster is a game changer for commercial and residential businesses that employ waste ponds.

- It’s an affordable, containerized, “Pond Water Machine in a Box™”.

- It’s designed and built for roll-in and roll-out deployment.

- Pondster has easy to use plug-n-play connections on the outside of the box.

- It offers operator friendly add-ons with existing connection ports.

- Requires low maintenance.

- Delivers quick results.

Internal equipment includes:

- Aeration blowers and piping systems.

- Water pumping and piping systems.

- Porous ceramic media system.

- Telemetry sensors and meters.

- Flex hose systems (inlet & outlet).

- Electrical systems (master control panel).

- Multi-compartment polypropylene tankage system (reinforced, covered and vented).

- Maximum power demand: 10 Kilowatts.

- Approximate shipping weight: 5,000 lbs.

Product

Pondster 30K MHP Pond

- Single tank system with external dims of 6.5′ w x 5′ H x 15’L. Tank fabricated using UV resistant PP sandwich panel construction.

- Shipping weight: 5000 lbs (estimated).

- Treatment capacity: 30,000 GPD of domestic lagoon wastewater to provide enhanced treatment performance necessary for stringent effluent limits related to BOD, TSS, and Ammonia.

- Equipped with flexible intake hose system with check valves and intake strainer.

- Equipped with flexible discharge hose system.

- Single electrical control panel with HOA switches (for two blowers and two pumps). Accommodates local power supply.

- Includes data logger system for pH and ORP water chemistry monitoring and reporting.

- Covered system with two aluminum access hatches.

- Utilizes advanced porous ceramic media for robust biofilm treatment of residual BOD, TSS, and TKN that commonly plague under-performing or out of compliance domestic/municipal lagoon systems.

Operational Requirements

- Designed to run automatically and unattended.

- Utilizes PLC based control system with touch screen display for ease of use.

- Equipped with remote control and monitoring capability (buyer must provide internet connection).

- Includes external flashing red alarm light and alarm horn.

- PLC will store Performance Data for Permit Reporting and Historical Performance Evaluation

- Detailed O&M Manual Provided

- Daily Labor Requirement: Automatic function does not require daily attendance (unless required by permit). PWT recommends conducting at least one weekly site visit to visually inspect the system while relying upon the remote monitoring system to inform the operator of system conditions in real time.

Pondster MHP Price

- MSRP Installed Price Estimate

$64,000 purchase price.

Bobber add-on feature is $2,500 per unit.

*Includes delivery and installation.

*Local contractor may be needed for power requirements. - Rental available at $2,560 a month.

5 year term. 3 year minimum.

Transferable to new operator owner.

Engineering Support

- Simple and effective preliminary design support.

- Detailed budgetary and final equipment proposals.

- Fully engineered solution development.

- Robust technical permitting packages.

- Detailed engineering calculations.

- 3D model design development.

- 2D CAD & pdf drawings.

- Performance specification in CSI format.

- Installation guide and O&M manuals.