Reclaiming Polluted Storm Water With OriginClear’s Electro Water Separation & Advanced Oxidation

Onsite Treatment Techniques Enable Flood-Affected Businesses to Avoid Trucking and Dumping Toxic Stormwater

Storm flooded Oklahoma City communities struggle with polluted and toxic floodwaters

Record-Setting Rain and Flooding

In June 2015, record-setting rain and flooding in the US state of Oklahoma led to the evacuation of homes and businesses, including industrial facilities with toxic materials. A local disaster recovery operator captured windblown water that had flooded the manufacturing site at Oklahoma City’s Prime Conduit, a manufacturer of electrical cables. This water became highly toxic in the process; and water technology company OriginClear partnered with licensee ECT Services & Solutions to treat this water so it could meet strict city requirements for draining it into the sewage system.

Oklahoma City’s Prime Conduit warehouse was flooded and water captured

from the electrical conduit manufacturer’s site was highly toxic

In this video, OriginClear reported the test of OriginClear’s high-speed, low energy Electro Water Separation™ breakthrough wastewater cleanup technology as an alternative to either water chemical treatment or offsite trucking for disposal.

In record time, OriginClear delivered a mobile demonstration system to the flooded facility, and treated contaminated water onsite for disposal into the city’s sewage system under the existing wastewater discharge permit.

OriginClear’s inTruck mobile EWS wastewater treatment system

OriginClear deployed a truck with a demonstration-scale, shippable EWS unit capable of treating 36 metric tons of contaminated water per day, with filter arrays to polish the final result to City standards. The unit consisted of an EWS module that used electrochemical reactions for the coagulation and removal of oil, grease, and total suspended solids, which eliminated most chemical oxygen demand (COD) and biological oxygen demand (BOD), and multistage media filtration for polishing of the remaining fraction, including Total Dissolved Solids (TDS). The mobile treatment skid was uniquely designed to meet the discharge specifications granted by the Oklahoma City Utilities Department.

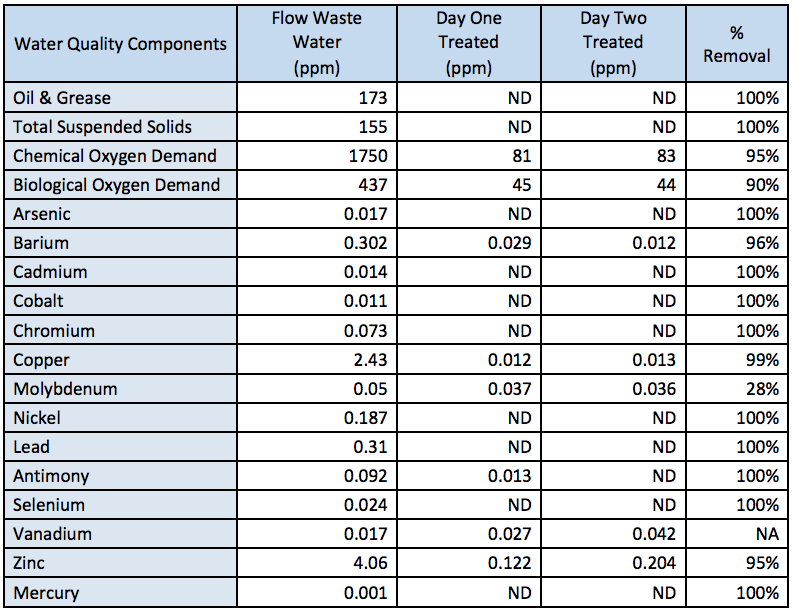

OriginClear’s process reduced most contaminants to non-detectable level; it reduced COD by 95 percent down to 81 parts per million (ppm); BOD down to 44 ppm; and heavy metals such as chromium, mercury, and copper by 99 percent or down to non-detectable as well. The result was essentially clear water, compliant with the local discharge regulations. Upon review of the independent lab analysis, the city approved disposal of the recovered water in its sewage system.

The effluent produced with onsite treatment met every specification of the Oklahoma City Utilities department. More than 77 percent of the contaminated water was converted into a disposable product that was discharged onsite, thus avoiding well disposal of wastewater and permanent removal from the water stream.

Toxic storm waters treated with OriginClear’s Electro Water Separation. Left image- removed total dissolved solids & toxic residues.

Right image- recaptured & clarified treated effluent water. Center image- fully cleaned and “polished” reclaimed storm water

for reuse or discharge to public municipal treatment facilities

“The OriginClear cleanup service surpassed our expectations,” said Talbott Howard, CEO of E3 (now ECT). “We knew this water had heavy metals and other industrial contaminants, but was diluted by a lot of recoverable water. The OriginClear ‘crash truck’ reduced visible contamination in the recovered water by 99.9%, making it appear clear to the eye. The city of Oklahoma permitted the water to be disposed directly into its sewer system, which is a huge cost benefit for our customers.”

After inspecting the process, Jeff Wells, owner of locally-based Wells Oil Company, said: “I think it’s a great opportunity for the state of Oklahoma to look at, especially in the oil and gas industry, when we deal with fracking, and disposing of the frack water. It could impact the bottom line of the smaller operators very effectively.”

The Perfect Storm of Industrial Flooding

Water which floods industrial facilities is complex mix which comes from the equipment and floor of these facilities – such as industrial solvents and lubricants, hydrocarbons, heavy metals, copper, mud, dirt, organic matter, salts, and pests that have been inhabiting the space. This toxic mix makes industrial stormwater one of the more challenging and dangerous waste waters to address.

Most industrial facilities are not well equipped to handle large volumes of stormwater following major storm events. Rapid deployment of hazardous waste equipment and personnel is essential to clean and transport of large volumes of contaminated stormwater onsite, for safe offsite disposal.

The issue experienced by industrial operators time and time again is that because such a wide variety of contaminants are present in industrial floodwater, traditional technologies are unable to properly recover water resources. Filters clog easily and require replacement every few hours, and biological treatment is slow and space-intensive, making onsite wastewater treatment nearly impossible.

OriginClear collection and storage tanks for pretreatment holding and post-treatment regulation

A US Environmental Protection Agency (EPA) report explains that special permits are required to dispose of wastewater because “runoff from rainfall or snowmelt that comes in contact with these [industrial] activities can pick up pollutants, and transport them directly to a nearby river, lake, or coastal water or indirectly via a storm sewer and degrade water quality.” Another EPA report continues, “This type of pollution is significant because, unlike the water that goes down a sink or toilet in your home, stormwater is untreated and flows directly to a lake, river, or the ocean.” Stormwater can change water chemistry, kill aquatic life, and lead to riparian habitat loss.

Enabling Better Recycling

The OriginClear partnership demonstrated that it could meet the serious engineering challenge of restoring clarity quickly to polluted waters, and enabling disposal back into existing municipal systems.

Electro Water Separation unit floats solids and toxins to the surface and removes them

Since the 2015 demonstration, OriginClear has further enhanced EWS with the 2016 addition of its patent-pending Advanced Oxidation™, which can now extract dissolved contaminants, which are otherwise difficult to remove without using chemicals such as chlorine. The combined EWS:AOx™ platform employs a combination of next-generation electrocoagulation, electroflotation, and electrooxidation processes across multiple stages to complete high-speed water treatment, with minimal consumables and low energy use. With the enhanced EWS:AOx, stormwater treatment uses only one system and takes minutes, not hours.

EWS:AOx removes up to 99 percent of free oil and suspended solids from water, as well as dissolved organics and a wide range of heavy metals. Service companies can then select the appropriate downstream polishing treatment to clean the water for disposal. The technology is used in Asia, Europe, and the United States to treat various types of wastewater, including polluted stormwater. It is used to separate clean water from its sludgy contaminants, minimizing hazardous disposal costs, and improving the performance and uptime of downstream treatment equipment such as membranes, ultrafiltration or activated carbon filters.

Implementing low-energy and customizable onsite treatment techniques enables flood-affected businesses to avoid trucking and dumping stormwater, meet environmental regulations, and ultimately lower water management costs. In this way, OriginClear’s complete treatment process provide a solution at the source of the problem while demonstrating the developing potential to address complex industrial wastewater challenges.

Summary of Test Results – 31 May 2015

Prime Conduit Inc. Oklahoma City Treatment of Cleanup Water

ND = Not Detectable (below instrument measuring tolerance)

NA = Not Applicable – no improvement recorded.

OriginClear’s Water Tech Network™

OriginClear licenses its proprietary technologies to forward-looking and innovative technology companies and offers a limited number of exclusive partnerships to proven water industry professionals that are driving the advancement of solutions and water treatment systems to fill the urgent need of the people of our planet for clean and reliable water. Find out if your company or operation qualifies to join our Water Tech Network. Become part of the team that operates Above and Beyond Clear Water™. Complete the form at bottom of page HERE.