Produced Water Made Reusable for Steam Boiler Influent and Agricultural Irrigation

High Quality De-Oiling and Reductions in Total Suspended Solids Enable Influent Specifications To Be Met For Water Softening and Steam Generation

SUMMARY

Between January and July of 2015, OriginClear has conducted operations treating an independent Bakersfield, California oil company’s energy produced water for re-use as steam boiler influent and for agricultural re-use. Due to the water quality characteristics of the East Bakersfield produced water the implemented process train, designated as Electro Water Separation™ (EWS) Petro, includes:

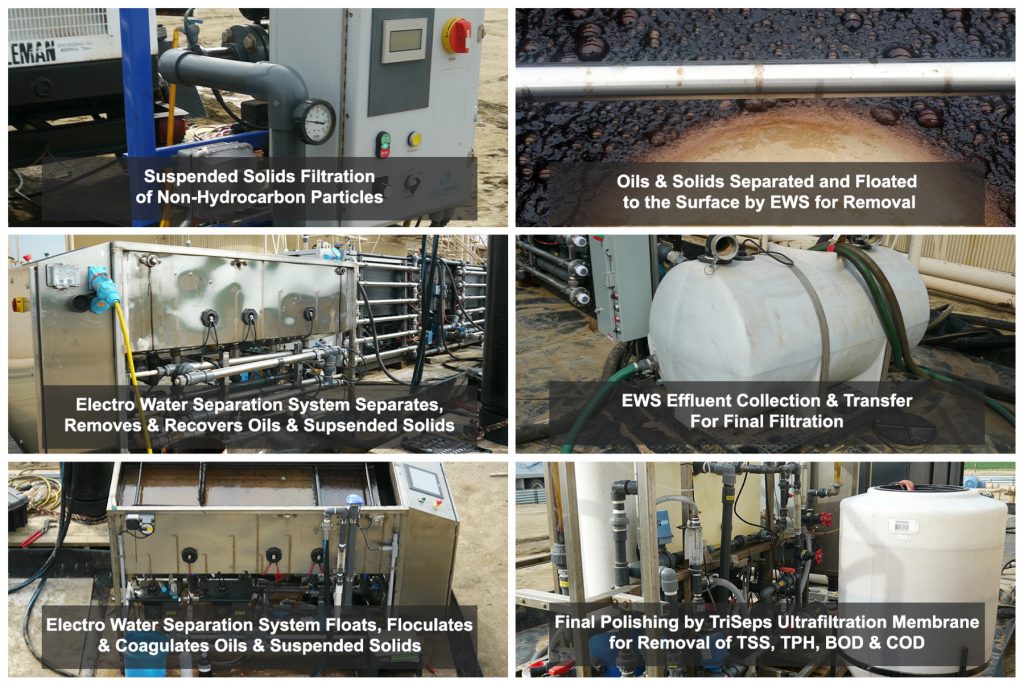

Bakersfield oilfield Electro Water Separation™ (EWS) produced water process train

OriginClear’s EWS Petro unit to achieve:

- Emulsion breaking

- Removal of suspended solids

- Recovery of petroleum hydrocarbons

- Reduction in biological activity

Followed by Ultrafiltration polishing with the TriSep iSep membrane for:

- Removal of TSS, TPH and BOD to below non-detect levels

BACKGROUND

The test company is an Energy & Power Independent operating in California, Texas and New Mexico. One of their major areas of production for is East Bakersfield. The hydrocarbons produced from this formation are heavy oils that require Cyclical Steam Stimulation to lower the viscosity of the oil and enable flow for adequate production.

To achieve this the company generates approximately 1,000 Barrels of Water Per Day (BWPD) of steam which is introduced into the producing formations. The volume of produced water that returns however is approximately 9,000 BWPD. Due to the characteristic low salinity of the East Bakersfield formation this produced water is generally near fresh quality from a total dissolved solids (TDS) perspective.

Due to the low salinity levels of the returning produced water, desalination may not be required in order to re-use the water for boiler steam feed. However, high quality de-oiling and reductions in Total Suspended Solids (TSS) are required to meet the influent specifications of the pre-existing softening facility and steam generator. The contents of this report therefore summarize the onsite operations conducted by OriginClear to treat the company’s produced water to a re-usable quality for additional Oil & Gas production.

PROCESS FLOW DIAGRAM

Based on the preliminary water quality data provided by the customer to OriginClear the following treatment objectives were identified for the proposed treatment process:

- Complete removal of suspended solids

- Complete removal of non-soluble petroleum hydrocarbons

- Reduction of biological activity

- Reduction of chemical oxygen demand

- To achieve these treatment objectives OriginClear implemented the EWS process flow, consisting of the following technologies:

1. Spiral Water Self Cleaning TSS filter

Intended for upfront suspended solids filtration of non-hydrocarbon particles greater than 25 µm in size

2. OriginClear’s Electro Water Separation system implemented to:

a. Break the incoming oil-water emulsion

b. De-oil the produced water

c. Recover the separated oil

d. Remove suspended solids

e. Reduce biological activity by removal and disinfection

f. Reduce Chemical Oxygen Demand by removal

Electro Water Separation In Action

3. Final polishing by TriSep’s iSep UltraFiltration membrane for the:

Removal of TSS, TPH, BOD and COD This combination is one version of OriginClear’s EWS Petro configuration, which is designed to achieve primary wastewater treatment for the oil & gas market.

RESULTS

The two principal objectives of the field operations at the site were to treat CSS produced water to a quality acceptable for re-use as steam generation and to do so in a sustainable fashion indicative of a properly engineered, low operational cost system. To be acceptable as steam influent the recycled produced water must be completely free of Oil & Grease and of suspended materials.

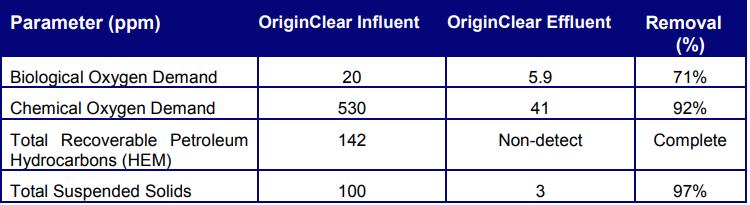

Water Quality Chart

*Water quality data generated by Zalco Laboratories, Sampled on February 18th 2015

As suggested by the long term turbidity removal data, the water quality information provided by Zalco Laboratories confirmed the successful treatment of CSS produced water to a quality acceptable for steam generation by OriginClear’s EWS Petro.

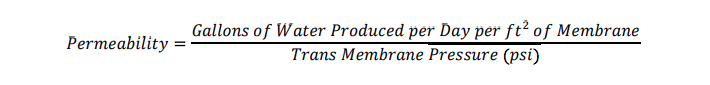

In addition to the water quality data generated; flow, pressure and temperature data are recorded multiple times daily to track the energy required to produce OriginClear effluent. The major metric for operational stability for the polishing unit is the ratio between water production and the pressure required to generate that water. The term for this efficiency metric is permeability and is calculated as:

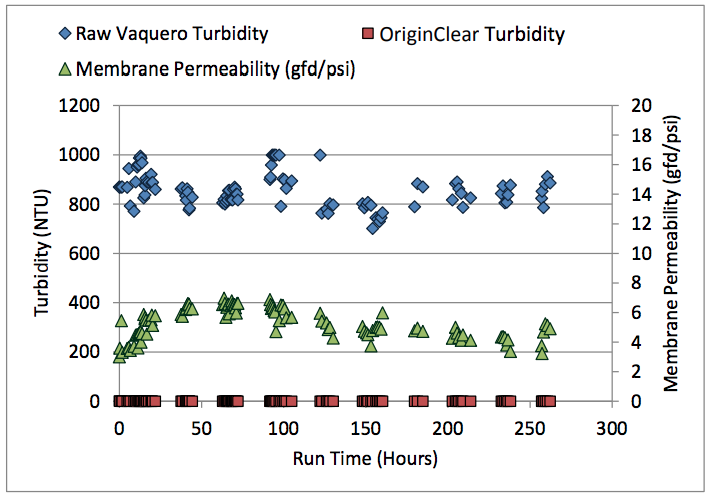

Figure 1 shows field data from the the customer’s Hershey Tank Battery site. Through the total run time the complete OriginClear process train has achieved an average turbidity reduction of greater than 99.9%. Additionally over that period of time no observable fouling has occurred to the membrane which can be seen in the permeability data.

Turbidity removal and membrane productivity data (permeability) at the Customers Hershey Tank Battery site, February to March 2015

Final Results

A picture below shows the progression of water clarification and the chemical and microbiological level metrics (as shown in the preceding chart) substantiate that OriginClear’s process train achieved an average turbidity reduction of greater than 99.9%.

OriginClear’s Water Tech Network™

OriginClear licenses its proprietary technologies to forward-looking and innovative technology companies and offers a limited number of exclusive partnerships to proven water industry professionals that are driving the advancement of solutions and water treatment systems to fill the urgent need of the people of our planet for clean and reliable water. Find out if your company or operation qualifies to join our Water Tech Network. Become part of the team that operates Above and Beyond Clear Water™. Complete the form at bottom of page HERE.